Featured Pieces

Please browse through these images of some pieces we have built for clients over the years. If you see something you would like to consider having built please contact us and we would be happy to provide a quote.

- Drop Leaf Table & Shawl Back Side Chair set in Cherry wood / Fireside finish

- Drop Leaf Table & Shawl Back Side Chair set in Cherry wood / Fireside finish

- Drop Leaf Table & Shawl Back Side Chair set in Cherry wood / Fireside finish

- Custom Office Set in Tiger Maple with Cinnamon finish. Drawer Bank in foreground is a file cabinet.

- Round Extension Table built of Tiger Maple wood in our Honey finish

- Round Extension Table built of Tiger Maple wood in our Honey finish

- Custom Kitchen Pantry Cupboard built in Cherry wood in our Amber finish

- Custom Kitchen Pantry Cupboard built in Cherry wood in our Amber finish

- Dresser Desk in Satin Black paint

- Dresser Desk in Satin Black paint

- Dresser Desk in Satin Black paint

- Dresser Desk Interior in Fireside on Tiger Maple wood

- Dresser Desk interior in Fireside on Tiger Maple wood

- Slant Front Desk built out of Tiger Maple wood in our Cinnamon finish

- Interior of a Slant Front Desk built out of Tiger Maple wood in our Cinnamon finish

- Dovetailed case corner on a Slant Front Desk built of Tiger Maple in our Cinnamon finish

- Interior of a Slant Front Desk built of Tiger Maple in our Cinnamon finish

- Low Bar Stool for a 36″ high counter. Tiger Maple wood in our Fireside finish with Black and Beige seat woven in a Diamond Pattern

- Set of Low Bar Stools for a 36″ high counter. Tiger Maple wood in our Fireside finish with Black and Beige seat woven in a Diamond Pattern

- Low Bar Stool for a 36″ high counter. Tiger Maple wood in our Fireside finish with Black and Beige seat woven in a Diamond Pattern

- Chimney Cupboard with a glass door built in Sugar Pine wood in our Honey finish

- Custom Storage cabinet built of Tiger Maple in our Cinnamon finish

- Custom Pie Safe built of Tiger Maple wood in our Cinnamon finish

- 2 Door Credenza built out of Cherry wood in our Amber finish

- Extension Table built out of Tiger Maple wood in our Cinnamon finish

- Extension Table built out of Tiger Maple wood in our Cinnamon finish

- Extension Table built out of Tiger Maple wood in our Cinnamon finish with a set of Shawl Back Side Chairs and Elder’s Arm Chairs

- Extension Table built out of Tiger Maple wood in our Cinnamon finish with a set of Shawl Back Side Chairs and Elder’s Arm Chairs

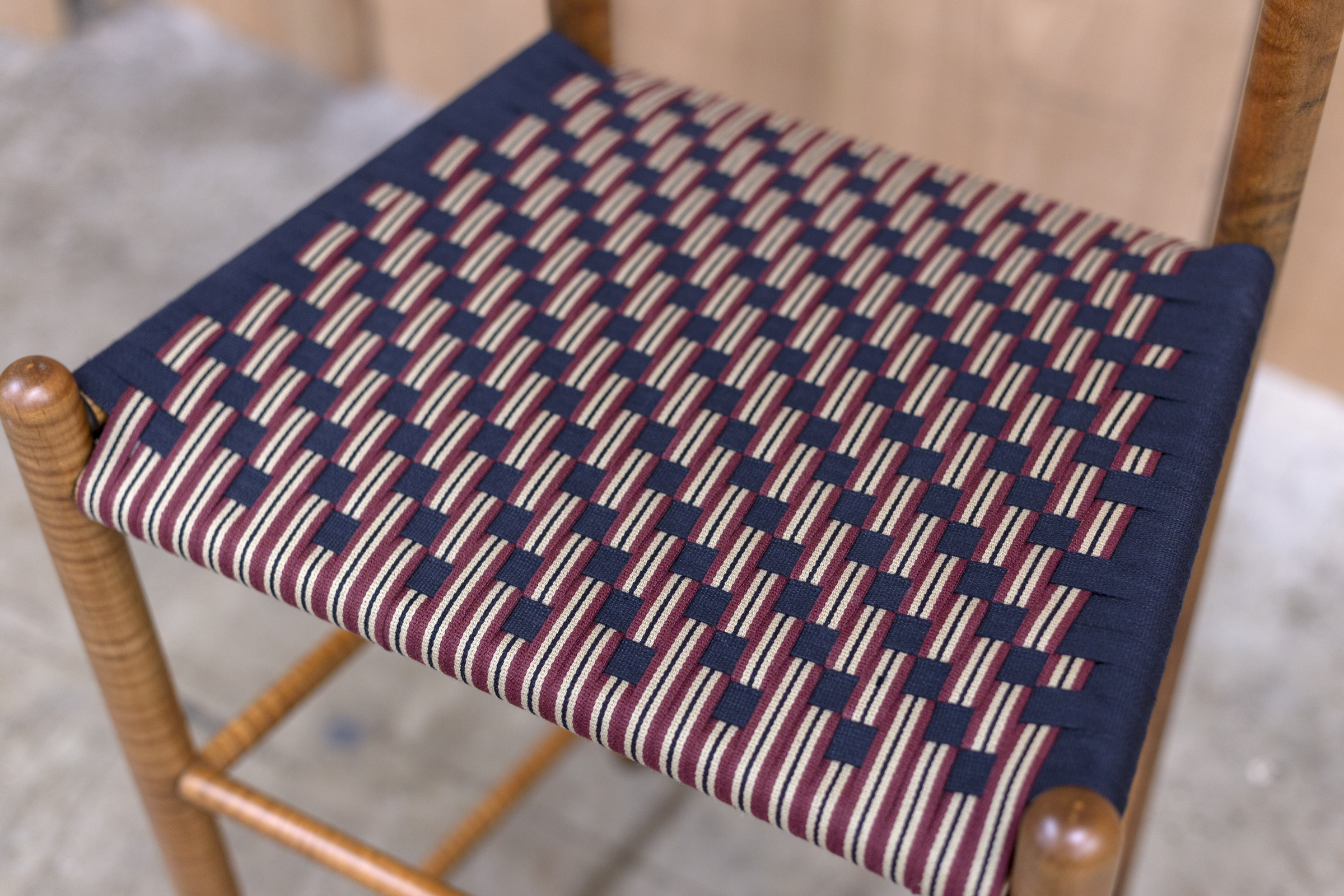

- Dropleaf Card Table & 3 Slat Side Chair in Cherry wood in our Amber finish. Chair seat is woven with Dark Blue & Beige Shaker Tape

- Delicate “Rule Joint” on the top of a Cherry Drop Leaf Table in our Fireside finish

- Custom Clothes Trees built out of Tiger Maple, Cherry and Ebony woods

- Custom Clothes Trees built out of Tiger Maple, Cherry and Ebony woods

- Cherry wood Sweater Cabinet in our Cinnamon finish

- Custom double pedestal Slant Front Desk built out of Tiger Maple wood in our Cinnamon finish

- Interior of a Custom double pedestal Slant Front Desk built out of Tiger Maple wood in our Cinnamon finish

- 4 Drawer Low Dresser in Satin Black paint

![]()

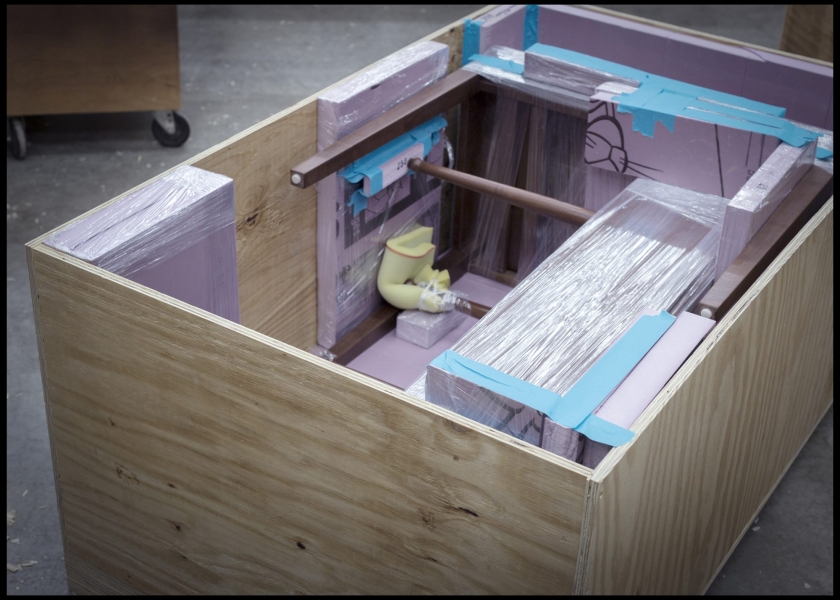

CRATING & SHIPPING OF ONE OF OUR LARGEST PIECES…some fine Pennsylvania Cherry wood & craftsmanship gets packed up for the journey to a Redwood forest in California

![]()

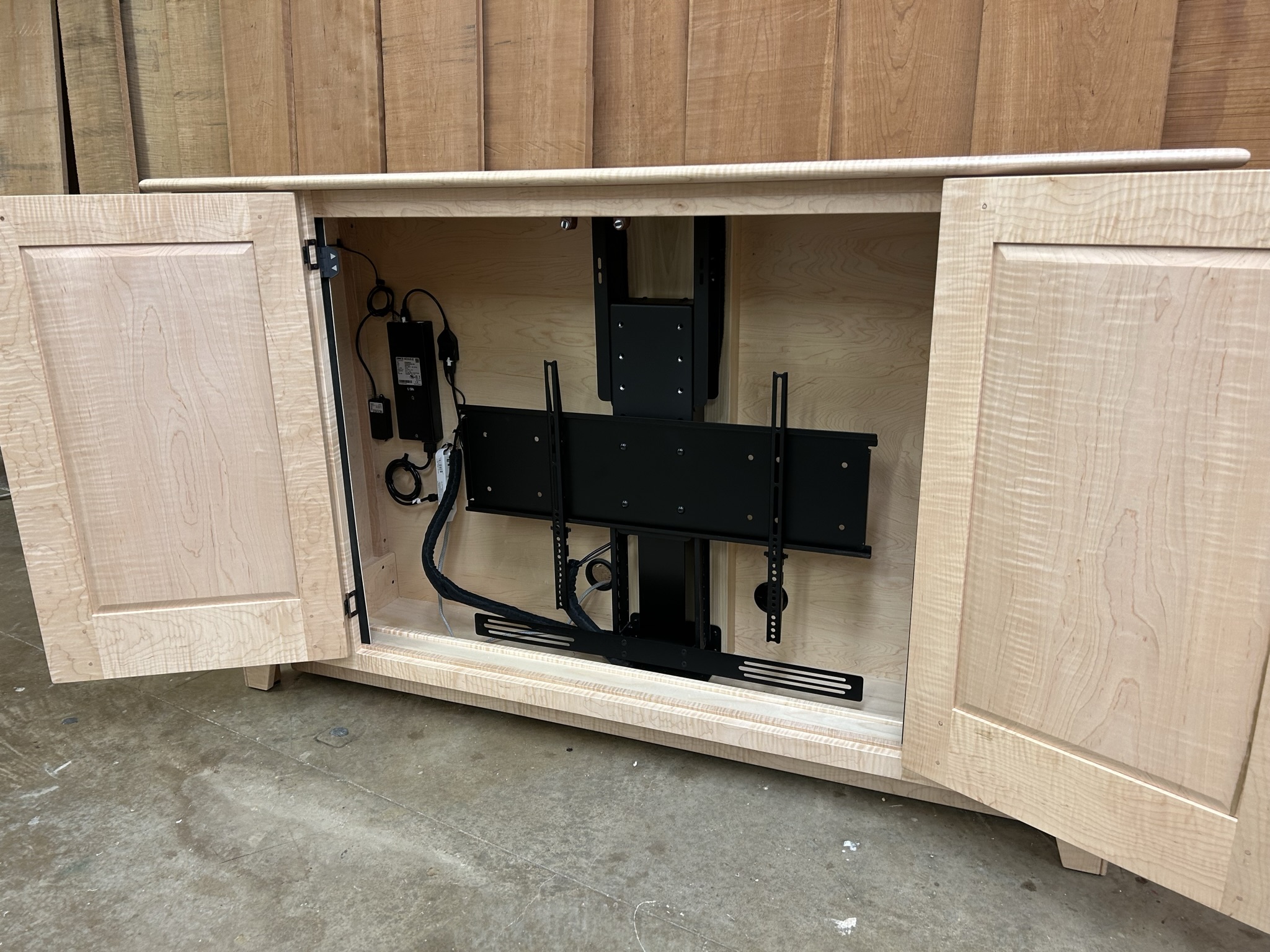

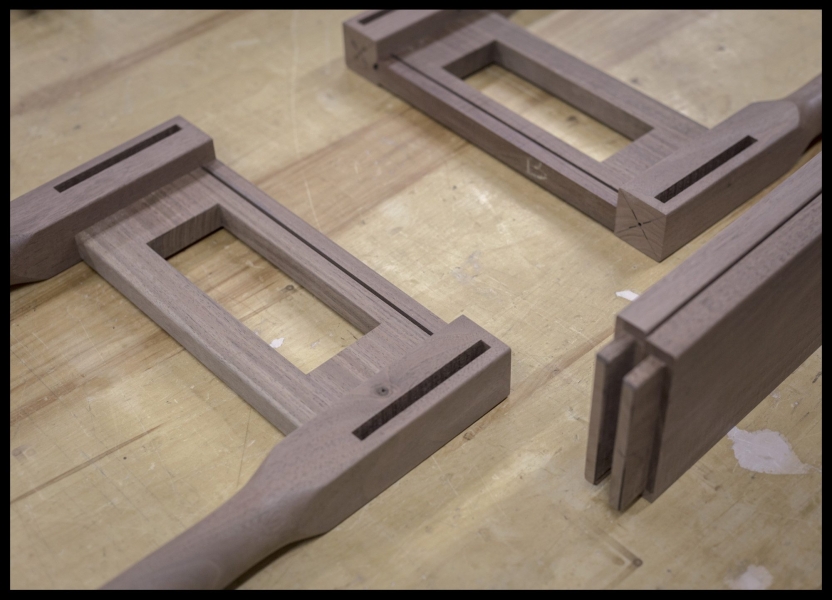

CREATING HEIRLOOMS FROM A FAMILY WALNUT TREE…another California friend seeks our shop out to turn her Father’s cherished East Coast American Black Walnut slabs into fine furniture to ship West

![]()

![]()

![]()